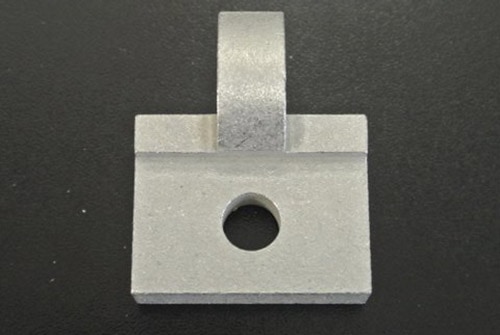

At Dynaburr, we are dedicated to providing high quality precision metal finishing at cost effective rates. In this featured project, we were contracted by a customer in the electrical industry to perform a mechanical silver and anti-tarnish plating of their powdered metal copper contact pivot. The nature and unique characteristics of our process renders the porosity sealing or “impregnation” step unnecessary, allowing us to offer the same part protection at a significant time and cost savings. The contact pivots, water, glass impact bead, chemicals, and silver materials were tumbled in lined barrel tanks for the initial mechanical plating. We employed our silver plating process for increased conductivity, followed by a post plating Tarniban dip to protect the silver from oxidation and tarnishing. A minimum plating thickness of 0.0003” and maximum thickness of 0.0005” were upheld. Parts were rinsed and spun dry in preparation for shipping.

The units were treated after a turnaround time of 2-3 days. All work took place at our ISO 9001:2008 certified facility, where exhaustive in process and final testing were administered including plating thickness and adhesion testing, and visual inspections. Our quality assurance protocols included the issuing of a certificate of conformance. For more information about this contact pivot plating project or our other value added precision finishing services please see the table below or contact us directly.